Against the backdrop of the rapid global development of unmanned system technologies, the Unmanned R&D Team of Easy Semiconductor Technology (Hong Kong) Limited has officially launched its high - performance self - developed servo steering gear. This technological breakthrough provides precise drive solutions for drones, robots, and automated equipment. With multiple innovative designs integrated, the product marks a significant leap in the company's technical strength in the field of high - end motion control.

I. Technological Breakthroughs: Dual Innovations in High Precision and High Reliability

1. Core Technical Architecture

The servo steering gear adopts a fully digital control scheme, equipped with a self - developed high - precision position feedback system. It achieves a positioning accuracy of up to 0.01° and a response speed 40% faster than traditional steering gears. Its core advantages are as follows:

Brushless Motor Drive: Utilizing a rare - earth permanent - magnet brushless motor combined with a low - backlash planetary gear set, it can output a peak torque of 120kg・cm while keeping the noise level below 45dB. This makes it suitable for precise applications such as aerial photography gimbals of drones and industrial robotic arms.

Dual - closed - loop Control Algorithm: Through the real - time coordination of the current loop and the position loop, the steering gear can maintain stable operation even in highly interfering environments. For example, when a drone encounters gusts, it can quickly correct attitude deviations, ensuring stable flight.

2. Modular Design and Environmental Adaptability

The team has introduced standardized interface modules for different application scenarios, supporting multiple communication protocols such as PWM, CANopen, and RS485, and being compatible with mainstream control platforms. In addition, the steering gear's housing is made of aviation - grade aluminum alloy and has passed the IP67 waterproof and dustproof certification. It can operate continuously in an environment ranging from - 20℃ to 60℃, meeting the requirements of harsh scenarios such as outdoor surveys and underwater robots.

II. Application Scenarios: Full - spectrum Coverage from Drones to Industrial Automation

1. In the Drone Field

In consumer - grade drones, this servo steering gear can achieve continuous 360° rotation, supporting real - time anti - shake for aerial photography lenses. Combined with the GPS positioning system, it can enhance image stability threefold. In the field of industrial drones, for example, in power line inspection scenarios, the robotic arm driven by the steering gear can precisely grasp foreign objects on high - voltage lines with a positioning error of less than 0.5mm.

2. In Service Robots and Industrial Automation

In the field of service robots, the steering gear is applied to bionic joint drives. For instance, the gripping arm of a catering robot can achieve a force control accuracy of 0.1N, ensuring zero damage when gripping glassware. In industrial production lines, multiple servo steering gears working in coordination can build a high - speed sorting system with a processing efficiency of 200 pieces per minute, which is 50% higher than traditional solutions.

III. R&D Journey: A Full - cycle Struggle from Technical Verification to Mass Production

The Unmanned R&D Team completed this project over two years. Key challenges overcome include:

Heat Dissipation Optimization in High - temperature Environments: Through the application of graphene coating and the design of a hollow - cup motor structure, the temperature rise during continuous operation of the steering gear is controlled within 25℃.

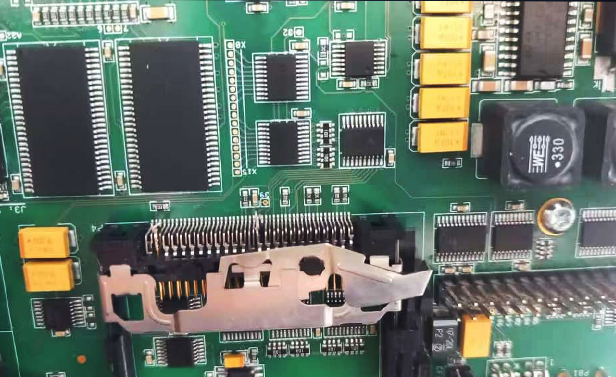

Electromagnetic Interference Resistance Design: A Faraday shielding mesh is added between circuit board layers to ensure that the steering gear is not affected by signal interference in strong electromagnetic environments such as substations. Currently, the servo steering gear has passed the ISO 9001 quality certification and has completed small - batch testing in three leading enterprises in the industry. Customer feedback shows that the failure rate is less than 0.1%.

IV. Industry Value: Promoting the Localization of Unmanned Systems

A spokesperson from the Unmanned R&D Team of Easy Semiconductor Technology (Hong Kong) Limited stated, "As a core component of motion control, servo steering gears have long been dependent on imports. Our self - development not only surpasses performance parameters but also reduces costs by 30%, providing a cost - effective 'Chinese solution' for the unmanned system industry."

In the future, the team plans to launch intelligent steering gears integrated with AI algorithms. By using built - in sensors to monitor wear status in real - time, predictive maintenance can be achieved, further improving the operation and maintenance efficiency of industrial equipment. The release of this product also lays a foundation for the company's expansion into overseas markets. Currently, technical cooperation intentions have been reached with automation enterprises in Singapore and Germany.