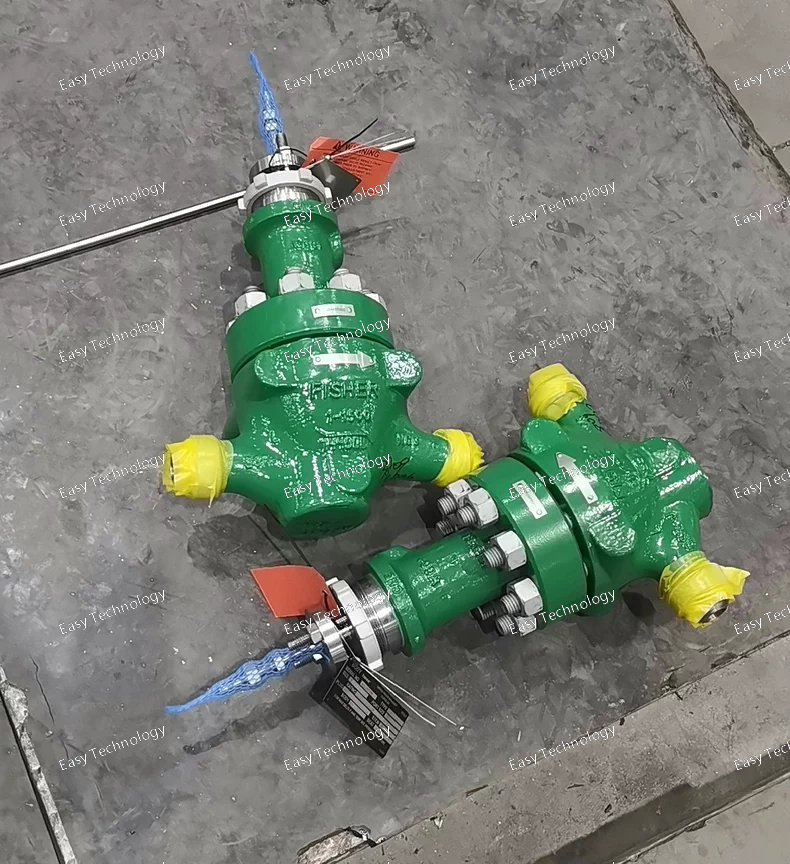

Key Specifications / Parameters Valve Type: Single‐port, globe‐style control valve with cage‐guiding and unbalanced plug (HPS version) Flow Direction: Normally “flow up” in the HPS configuration (for linear or equal‑percentage trims) Sizes (in certain configurations): NPS 1 to 3 for CL900 and CL1500; NPS 1 to 2 for CL2500 in HPS‑C specification Pressure / Temperature Capability: According to the cryogenic version, the HPS‑C variant is rated from about ‑198 °C (‑325 °F) up to 316 °C (600 °F) in applicable materials Seat Construction: Metal seats standard for HP series; tight shutoff capability (Class IV standard, optional Class V) Flow Characteristics: Equal percentage, linear, or modified equal percentage depending on trim Construction Materials: Body/bonnet and trim options for high‐pressure service; spiral‐wound gaskets standard; NACE compliant materials available Applications: High‐pressure, high‐temperature, heavy‐industrial process control (refining, chemical, power) Features: Rugged construction for full pressure‐drop capability; quick change trim; improved stem guiding for vibration/noise reduction