The ABB GINT-5611C inverter drive module is designed for advanced industrial applications, delivering high efficiency and precise control in motor operations across various sectors including manufacturing, processing, and automation.

The ABB GINT-5611C inverter drive module is designed for advanced industrial applications, delivering high efficiency and precise control in motor operations across various sectors including manufacturing, processing, and automation.

WhatsApp

WhatsApp

Power Rating:5611W

Frequency Range:0-50Hz

Operating Temperature:-10°C to +50°C

Protection Class:IP54

Control Interface:Modular and Expandable

Communication Protocol:CANopen, Profinet, EtherCAT

Motor Compatibility:Up to 11kW

Safety Features:SIL2 compliant

Maintenance Requirements:Minimal, self-diagnostic

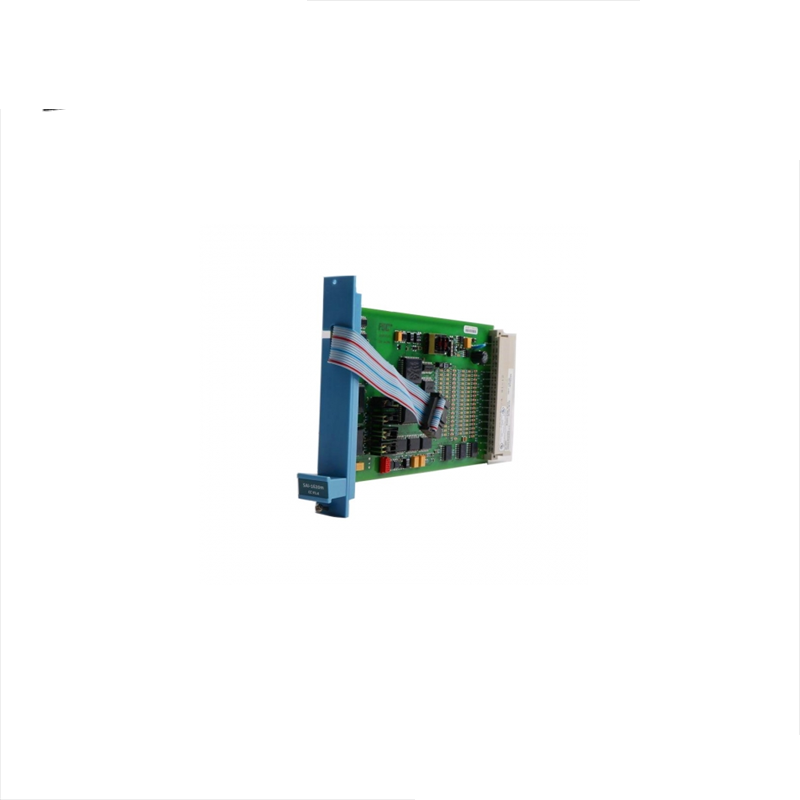

Experience unparalleled precision in industrial automation with our ABB GINT-5611C Inverter Drive Plate. This advanced piece of machinery is designed to optimize energy consumption and system performance, ensuring seamless integration with a wide array of industrial processes.

Featuring a modular design, our drive plate allows for easy customization and scalability, meeting the evolving needs of your production line. Whether you’re dealing with textile manufacturing, printing, rubber processing, or woodworking applications, this drive plate delivers unmatched efficiency.

Crafted with robust materials, it withstands demanding industrial environments, ensuring longevity and reliability. With its wide operating temperature range and IP54 protection class, it’s suitable for a variety of conditions, from cool warehouses to hot workshops.

The ABB GINT-5611C supports multiple communication protocols, including CANopen, Profinet, and EtherCAT, facilitating seamless connectivity with other systems and equipment. This feature-rich drive plate is also equipped with safety functions compliant with SIL2 standards, enhancing workplace safety.

Ease of maintenance is a key aspect of this product. It comes with built-in diagnostic capabilities, allowing for proactive monitoring and quick resolution of any issues. This ensures minimal downtime and maximum operational efficiency, making it an ideal choice for modern industrial operations.