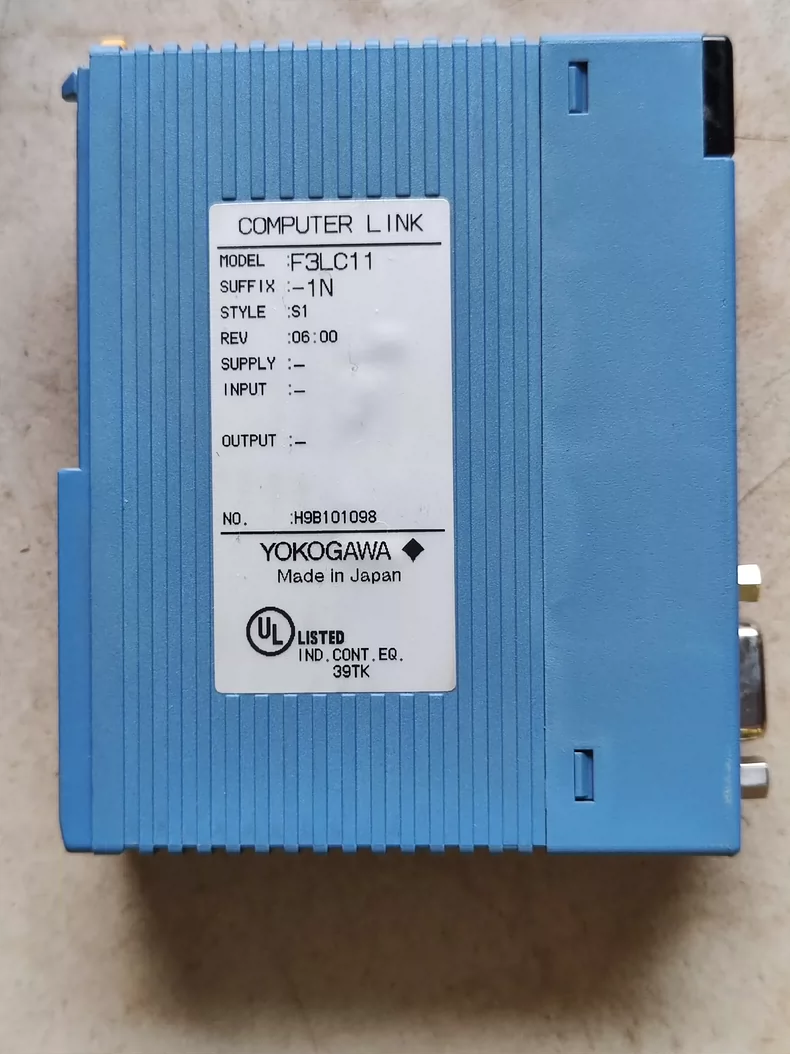

The Yokogawa F3LC11-1N is a single-loop control module for the FA-M3 series Programmable Logic Controllers (PLCs). It is designed to provide advanced process control capabilities, including PID control, for continuous processes such as temperature, pressure, flow, and level regulation. This module integrates seamlessly with the FA-M3 system, offering high precision and reliability for industrial automation applications.