Key Parameters

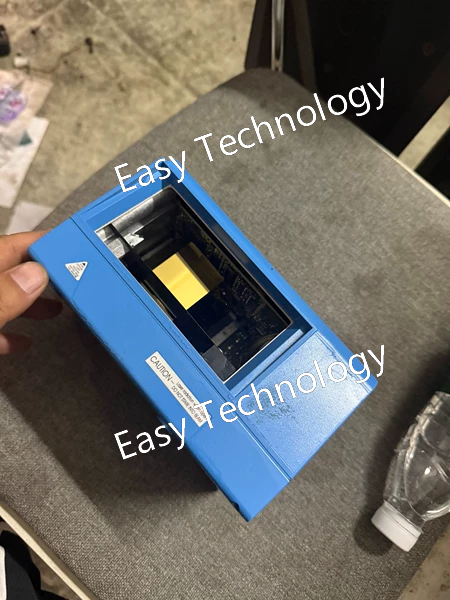

Sensor Type: Machine vision sensor, with integrated camera and processing unit

Resolution: 1280 x 1024 pixels, providing high-definition imaging for detailed object analysis and precise inspection

Frame Rate: Up to 30 fps (frames per second) for high-speed applications, allowing for real-time image processing and object detection

Lighting: Integrated lighting options (e.g., LED, adjustable brightness), suitable for detecting objects in various lighting conditions and environments

Processing: Embedded processing power with advanced algorithms for image analysis, object detection, pattern recognition, and barcode reading

Interface:

Ethernet for fast and reliable data transfer and communication

I/O Ports: Multiple input and output options for integration with PLCs, robotics, and other automation devices

Output Type:

Ethernet/IP, PROFINET, and RS-232 for easy integration into industrial control systems

Digital I/O for trigger events or signaling between sensors and machines

Supply Voltage: 24 V DC, ensuring compatibility with a wide range of industrial control systems

Protection Class: IP65 (dust-tight and protected against water jets), ensuring reliable operation in industrial environments

Temperature Range: 0°C to +50°C, making it suitable for use in typical industrial conditions

Mounting Type: Compact design, suitable for mounting in tight spaces or on machines with limited room for sensor placement

Applications:

Object Detection: Ideal for detecting and tracking objects on production lines, ensuring correct positioning or placement for further processing.

Quality Control: Used for visual inspections, detecting defects such as scratches, cracks, or missing parts, and ensuring product quality during production.

Barcode Reading: Capable of reading 1D and 2D barcodes, QR codes, and Data Matrix codes for automatic identification and traceability of parts and products.

Pattern Recognition: Performs pattern matching and recognition tasks, identifying specific object shapes or features on production lines.

Assembly Verification: Ensures that components are assembled correctly, checking for the presence or alignment of parts in automated assembly processes.

Surface Inspection: Detects surface defects in materials or products by analyzing the object’s visual characteristics, ensuring the desired surface quality.

Additional Features:

Real-Time Image Processing: The VMD520-2000 offers fast image processing with real-time feedback, making it suitable for high-speed production lines where immediate decision-making is required.

Advanced Algorithms: Equipped with powerful algorithms for tasks like pattern recognition, defect detection, barcode reading, and position verification.

High-Resolution Imaging: With 1280 x 1024 pixels resolution, it delivers high-quality images that ensure precise and accurate object detection and quality inspection.

Versatile Connectivity: The Ethernet/IP, PROFINET, and RS-232 communication protocols provide flexibility for integrating with a wide variety of industrial systems.

Durable Design: IP65 protection rating ensures the sensor is protected against dust and water, making it suitable for demanding industrial environments.

Compact Form Factor: Its small, compact design allows for easy installation in tight spaces or on machines with limited installation area.