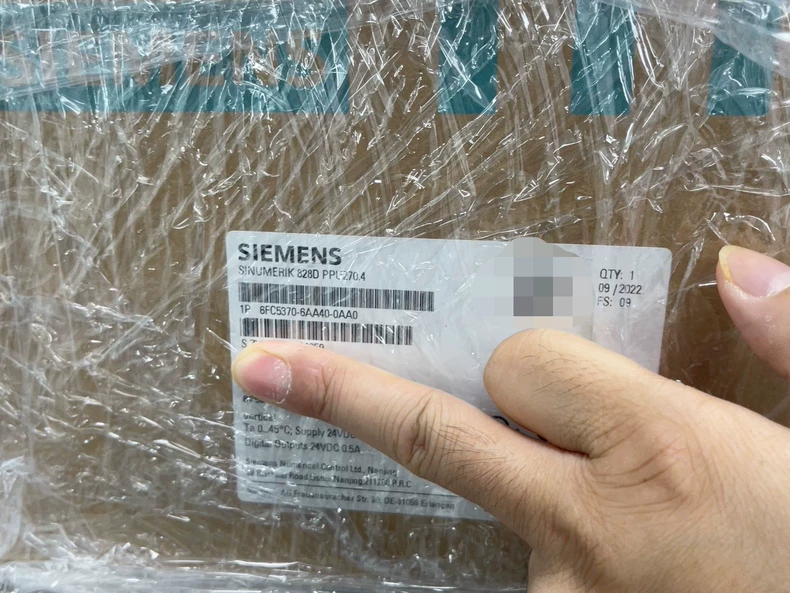

The Siemens 6FC5370-6AA40-0AA0 is a motion control module designed for use in Siemens' SINAMICS drive systems, specifically for motion control applications in industries such as automated manufacturing, machine tools, and robotics. This module is used to manage high-precision motor drives, ensuring synchronized and accurate motion control, which is essential for tasks such as positioning, speed control, and torque management.