Key Features:

Type: Human-Machine Interface (HMI)

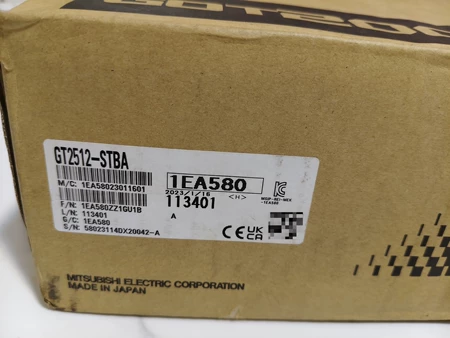

Model: GT2512-STBA

Series: GT25 Series

Display Type:

Screen Size: 12.1 inches

Resolution: 800 x 600 pixels (SVGA)

Touchscreen: Resistive touchscreen for precise input and operation

Color Display: 64K color TFT LCD for bright and clear visual output

High Performance:

Fast processing and response time for smooth user interface interaction

High-speed graphics rendering for dynamic system displays

Multi-Protocol Communication:

Supports communication with Mitsubishi PLCs, including MELSEC Q Series, FX5 Series, and iQ-R Series

Compatible with other industrial devices through Ethernet, RS-232, and RS-485 communication interfaces

Supports Modbus TCP, MELSEC Communication Protocols, and other industrial network standards

User-Friendly Interface:

Simple configuration and operation through the intuitive GT Designer3 software

Customizable screen layouts, including graphical representations of systems and equipment

Built-in library of pre-configured graphical objects for easy display creation

Multi-Touch Support: Enables multi-touch gestures for efficient control and navigation

Data Logging & Monitoring: Capable of storing operational data for monitoring, trending, and analysis

Real-Time Control: Provides real-time control, data acquisition, and system monitoring

Alarms & Notifications: Supports the display of system alarms, status messages, and warning notifications in real-time

Flexible Mounting: Can be mounted on control panels, machinery, or embedded in industrial environments

Specifications / Parameters:

Display:

Screen Size: 12.1 inches

Resolution: 800 x 600 pixels (SVGA)

Display Type: Color TFT LCD, 64K colors

Touchscreen: Resistive touchscreen for accurate touch input

Communication:

Ethernet Port (100Base-TX) for fast communication with PLCs and devices

RS-232/RS-485 Serial Ports for serial communication

Supports Modbus TCP and MELSEC communication protocols

CPU:

Processing Power: 32-bit processor for high-speed performance

Memory: 32 MB Flash memory for storing user programs and graphics

Power Supply:

Voltage: 24 V DC

Power Consumption: Approx. 22 W

Operating Temperature:

Ambient Temperature: 0°C to +50°C

Storage Temperature: -20°C to +60°C

Dimensions:

Width: 291 mm

Height: 216 mm

Depth: 50 mm

Weight: Approx. 1.8 kg

Mounting: Suitable for panel mounting or embedded installations

Protection Class: IP65 (Front) for protection against dust and water jets

Humidification: 10% to 90% RH (non-condensing)

Status Indicators: LED indicators for power and communication status

Expansion: Capable of expansion with additional communication modules or I/O devices through standard protocols like Modbus or CC-Link

Applications:

Industrial Automation: Provides an intuitive user interface for controlling and monitoring industrial processes, machinery, and production lines

CNC Machines: Ideal for use in CNC machines for real-time monitoring, operation, and system diagnostics

Material Handling: Used in material handling systems for monitoring the status and controlling operations such as conveyor systems

Packaging Machines: Controls and monitors packaging systems, displaying real-time production data and system parameters

Machine Tools: Provides a user interface for controlling and monitoring machine tools, ensuring smooth and precise operations

HVAC Systems: Controls heating, ventilation, and air conditioning systems, allowing for real-time parameter adjustments and system monitoring

Energy Management: Used in energy management systems to monitor energy consumption, optimize usage, and track performance

Factory Control Systems: Offers real-time monitoring and control for various factory automation tasks, improving efficiency and troubleshooting

Robotics: Enables operator control of robotic systems with real-time feedback, monitoring, and adjustments