Key Features:

Type: Variable Frequency Drive (VFD)

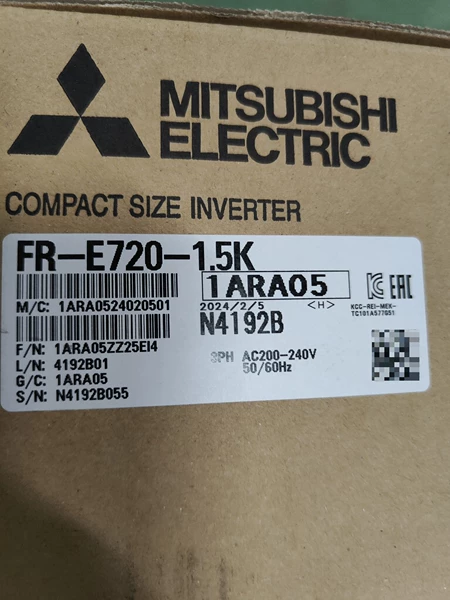

Model: FR-E720-1.5K

Series: FR-E720 Series

Motor Control:

High-performance control for induction motors and permanent magnet synchronous motors (PMSM)

Vector control for high-torque, low-speed operation, and precise motor performance

PID control for automatic regulation of process variables such as pressure, temperature, and flow

Compact Design:

Space-saving and compact for easy installation in control panels and machinery cabinets

DIN rail mountable for flexible installation in diverse environments

Energy Efficiency:

Advanced energy-saving functions to reduce operational costs

Auto-tuning for optimizing motor performance, ensuring optimal efficiency

User-Friendly Interface:

Equipped with an easy-to-use LCD display for monitoring system status, motor parameters, and diagnostics

Quick settings with intuitive interface for fast installation and setup

Protection Features:

Includes overload, overvoltage, overcurrent, and short-circuit protection for safe and reliable operation

Built-in protection functions to safeguard the drive and connected equipment from damage

Communication Options:

Supports RS-485 communication, including Modbus RTU protocol, for easy integration into networked control systems

Option to connect with MELSEC PLCs or other automation devices for advanced control

Specifications / Parameters:

Power Supply:

Input Voltage: 200-240 V AC (single-phase)

Input Current: 8.4 A

Power Consumption: Approx. 1.8 kVA

Frequency Range: 0 to 400 Hz

Motor Compatibility:

Compatible with three-phase induction motors and permanent magnet synchronous motors (PMSM)

Output Power:

Rated Output Power: 1.5 kW

Output Voltage: 0 to the input voltage (typically 200-240 V AC)

Rated Output Current: 8.4 A

Control Method:

Vector Control for high torque, even at low speeds

V/F control for standard operations

PID Control: Allows precise control of process variables like temperature, speed, and pressure

Communication:

RS-485 port for communication with external devices, PLCs, and control networks

Modbus RTU protocol support for seamless integration

Optional Expansion Modules for additional communication options like Ethernet/IP or CC-Link

Cooling Method:

Natural air cooling (convection), no additional external cooling required

Environment:

Operating Temperature: 0°C to +50°C

Storage Temperature: -20°C to +60°C

Humidity: 20% to 90% RH (non-condensing)

Altitude: Up to 1000 m (above sea level) without derating

Protection Class:

IP20 (for indoor use), providing protection against solid objects greater than 12mm in size and limited water ingress

Dimensions:

Width: 150 mm

Height: 180 mm

Depth: 150 mm

Weight: Approx. 1.5 kg

Status Indicators:

LED Indicators and LCD display for easy monitoring of operational status, error codes, and diagnostics

Real-time monitoring of motor performance, output frequency, and input voltage

Overload Capacity:

150% of rated current for 60 seconds

200% of rated current for 5 seconds

Applications:

HVAC Systems: Controls motors in heating, ventilation, and air conditioning systems, ensuring precise regulation of motor speed

Pumps and Fans: Ideal for controlling pumps and fans in industrial systems, optimizing energy consumption and process efficiency

Conveyors: Used in conveyor belts for precise speed control, ensuring smooth material handling and processing

CNC Machines: Provides speed and torque control for motors in CNC machines to enhance precision in machining operations

Packaging Machinery: Controls motors in packaging systems, including labeling, bottling, and sorting machines

Food and Beverage: Controls motors for machines in food processing, including mixers, blenders, and filling machines

Textile Industry: Used in spinning, weaving, and knitting machines where precise speed control is essential

Material Handling: Ideal for controlling material handling systems such as automated guided vehicles (AGVs) and robotic arms