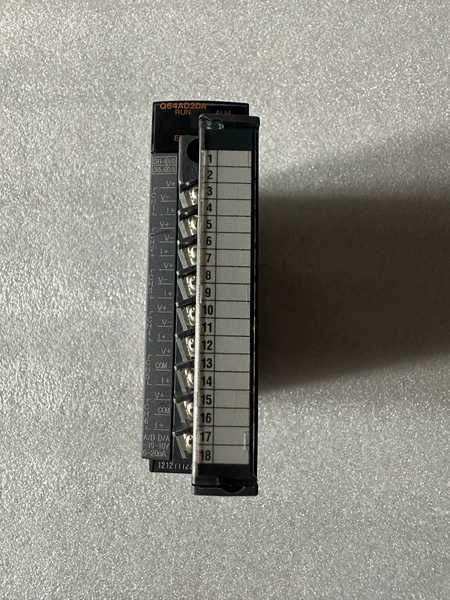

The Mitsubishi Q64AD2DA is an analog input/output (I/O) module designed for MELSEC-Q series PLCs. It provides precise analog data handling with the ability to receive analog input signals from sensors and transmit analog output signals to control devices. The module is ideal for applications that require high-precision control, such as temperature regulation, speed control, and pressure monitoring.