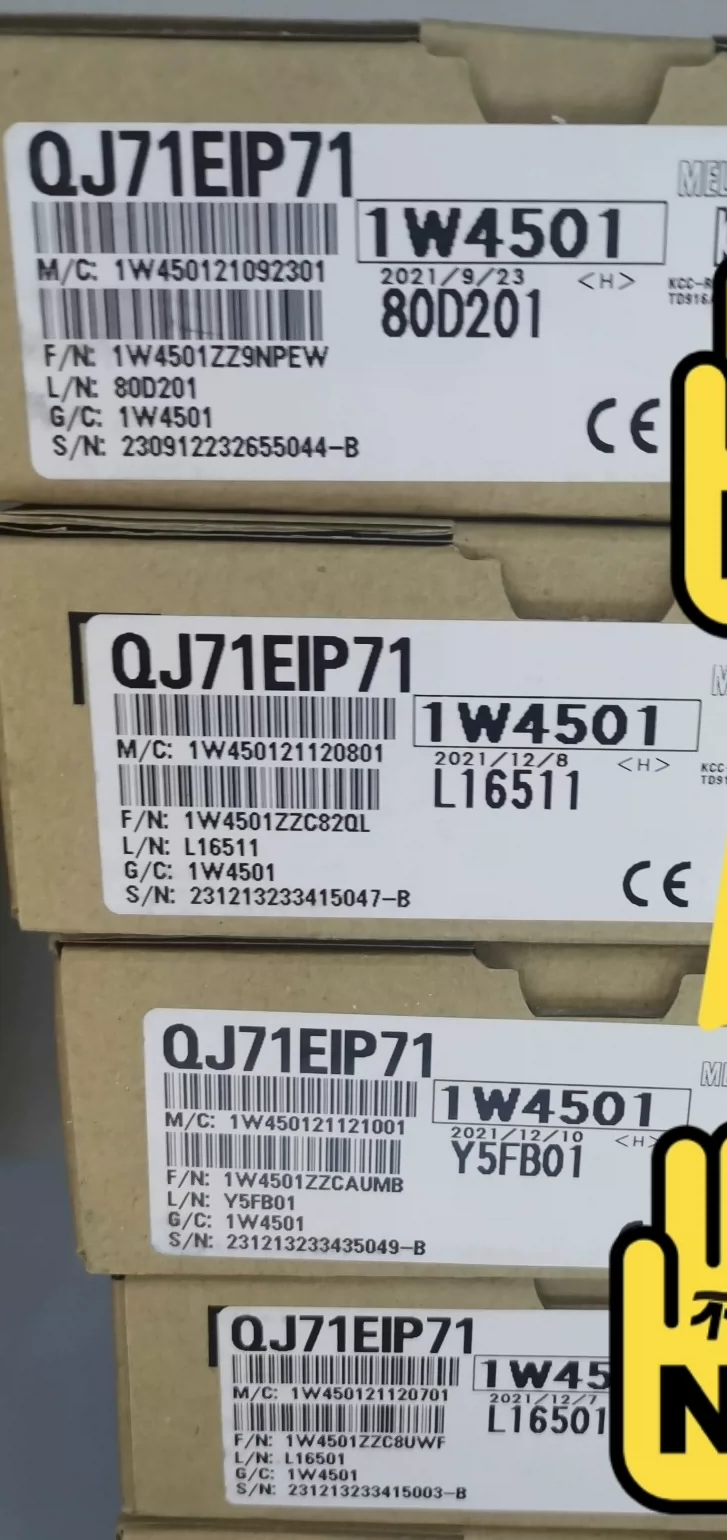

The Mitsubishi QJ71EIP71 is an Ethernet communication module designed for use with the MELSEC Q series PLCs. This module provides high-speed, reliable communication over Ethernet networks, allowing the PLC to connect to other PLCs, computers, and industrial equipment using standard Ethernet protocols. It supports both TCP/IP and UDP protocols, making it versatile for a variety of industrial communication needs such as remote monitoring, data exchange, and network integration.