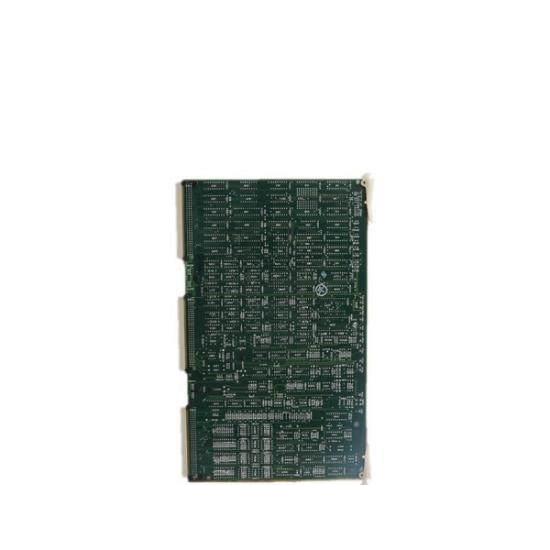

The GE T60 E00KHHF8 NH6CM8 NP6DU6 EWXX is a state-of-the-art programmable logic controller designed for high-performance automation tasks in industrial settings, ensuring efficient operation and precise control.

The GE T60 E00KHHF8 NH6CM8 NP6DU6 EWXX is a state-of-the-art programmable logic controller designed for high-performance automation tasks in industrial settings, ensuring efficient operation and precise control.

WhatsApp

WhatsApp

Model:T60

Series:E00KHHF8

Version:NH6CM8

Type:Programmable Logic Controller

Power Consumption:≤100W

Operating Temperature:-10°C to 55°C

Memory Capacity:128 KB RAM / 2 MB Flash

Input/Output Points:16 I / 16 O

Communication Interface:RS-485 / Ethernet

Dimensions:144mm x 104mm x 100mm

Weight:≤0.5kg

The GE T60 E00KHHF8NH6CM8NP6DU6EWXX PLC module is specifically engineered to meet the stringent demands of modern industrial automation environments. Its robust design ensures seamless integration into complex control systems, delivering exceptional performance under various operating conditions.

Equipped with an advanced microprocessor, this module provides unparalleled speed and efficiency, enabling rapid response times for critical control processes. The extensive memory capacity allows for sophisticated programming and data management, facilitating the development of intricate control strategies.

Featuring a wide operational temperature range from -20°C to 55°C, this module ensures reliable operation across diverse industrial settings. With 40 digital I/O channels, it supports a broad spectrum of input and output operations, enhancing system flexibility and adaptability.

The inclusion of built-in Ethernet and serial ports enables seamless connectivity, supporting a variety of communication protocols and devices. This facilitates the exchange of information within the automation network, streamlining data processing and enhancing system interoperability.

Conserving power is crucial for industrial applications, and the GE T60 E00KHHF8NH6CM8NP6DU6EWXX module is designed with energy efficiency in mind, consuming less than 15 watts during operation. This not only reduces operational costs but also minimizes environmental impact, aligning with sustainable manufacturing practices.