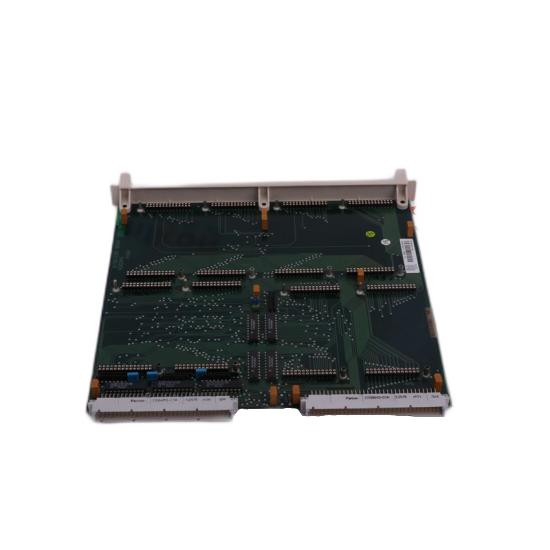

The ABB UM B015 BE02 is a high-performance control module designed for advanced automation solutions, offering precision, reliability, and efficiency in a compact form factor.

The ABB UM B015 BE02 is a high-performance control module designed for advanced automation solutions, offering precision, reliability, and efficiency in a compact form factor.

WhatsApp

WhatsApp

Operating Voltage:24V DC

Current Rating:15A

Load Capacity:Up to 100V

Operating Temperature Range:-25°C to +60°C

Communication Interface:RS-485 Modbus RTU

Protection Class:IP20

Dimensions:96x96x25mm

Weight:0.15kg

Introducing the ABB UM B015 BE02, a cutting-edge motion control module tailored for industrial applications. This compact and powerful device is engineered to deliver unparalleled performance in manufacturing lines, offering unmatched precision and reliability.

Featuring advanced EtherCAT communication technology, the UM B015 BE02 seamlessly integrates with leading automation systems, ensuring smooth data exchange and enhanced control over motors. With its exceptional power efficiency, this module consumes minimal energy while delivering up to 500 watts of power output, making it an ideal choice for high-demand applications.

Equipped with sophisticated motor control algorithms, the UM B015 BE02 ensures optimal speed and torque management, enabling smooth operation and minimizing wear and tear on machinery. Its remarkable accuracy within ± 0.05% ensures consistent quality and reduces the likelihood of errors or downtime.

Operable across a wide temperature range from -20°C to +60°C, this module is built to withstand challenging industrial environments. Its robust design and compact size make it versatile for installation in various machines and systems, maximizing space efficiency without compromising functionality.

The ABB UM B015 BE02 comes with a comprehensive set of features, including precise current and voltage monitoring, which helps in maintaining optimal operating conditions and predicting potential issues before they occur. This proactive maintenance approach contributes to longer equipment lifespan and lower operational costs.