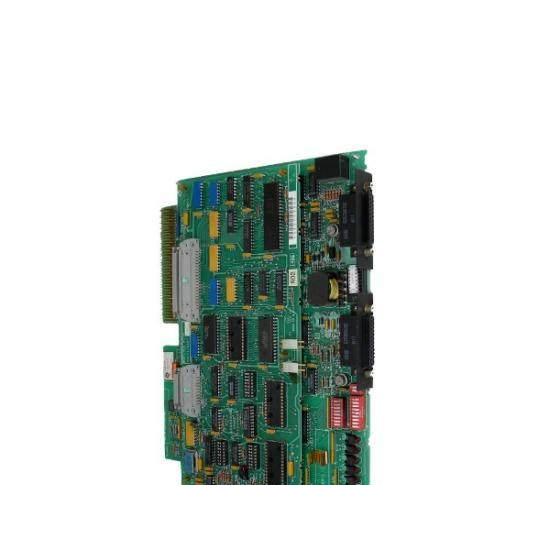

The GE Fanuc IC660CBB902 Versamax PLC is an advanced industrial control system designed for seamless integration and efficient operation in a variety of industrial environments.

The GE Fanuc IC660CBB902 Versamax PLC is an advanced industrial control system designed for seamless integration and efficient operation in a variety of industrial environments.

WhatsApp

WhatsApp

Model:IC660CBB902

Type:Versamax PLC

Manufacturer:GE Fanuc

Operating System:Windows Embedded Standard

Processor:Intel Xeon E5-2600

RAM Capacity:32GB DDR4

Flash Memory:500GB SSD

Network Interface:Ethernet 10/100/1000 Mbps

Power Consumption:100W

Operating Temperature:-20°C to 55°C

Dimensions:120mm x 100mm x 30mm

Weight:0.5kg

Introducing the GE-FANUC IC660CBB902 VersaMax PLC, a cost-effective and powerful solution for industrial automation. This PLC is equipped with advanced features that cater to a multitude of applications, from basic to highly complex scenarios, ensuring smooth operation across diverse industries.

Featuring a versatile processor capable of delivering up to 128 MIPS, this PLC ensures swift execution and responsiveness. With up to 64 KB of RAM and ROM, it offers ample storage space for program logic and data management.

The integrated GE Proficy system provides a comprehensive environment for programming, configuration, and diagnostics, simplifying the setup and maintenance processes. The support for Ethernet, DeviceNet, and Modbus RTU protocols enables seamless communication with other industrial devices, facilitating integration within any manufacturing ecosystem.

For those requiring precise temperature control, the TCM module is compatible with a variety of applications such as plastic extrusion, furnaces, and injection molding, ensuring optimal performance in critical processes. The Digital Servo Module (DSM) adds another layer of functionality by providing two-axis digital motion control, ideal for point-to-point or synchronous movement in conjunction with analog or digital servos.

The compact design of the VersaMax PLC allows for easy installation on DIN rails, making it a space-efficient solution. Moreover, its efficient power consumption contributes to lower operational costs, aligning well with sustainable manufacturing practices.