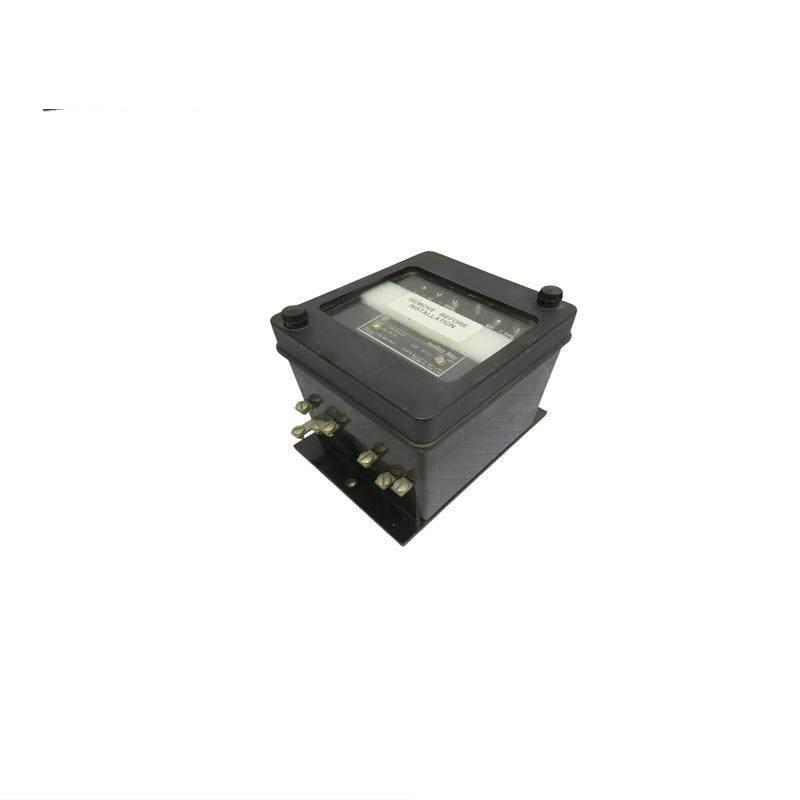

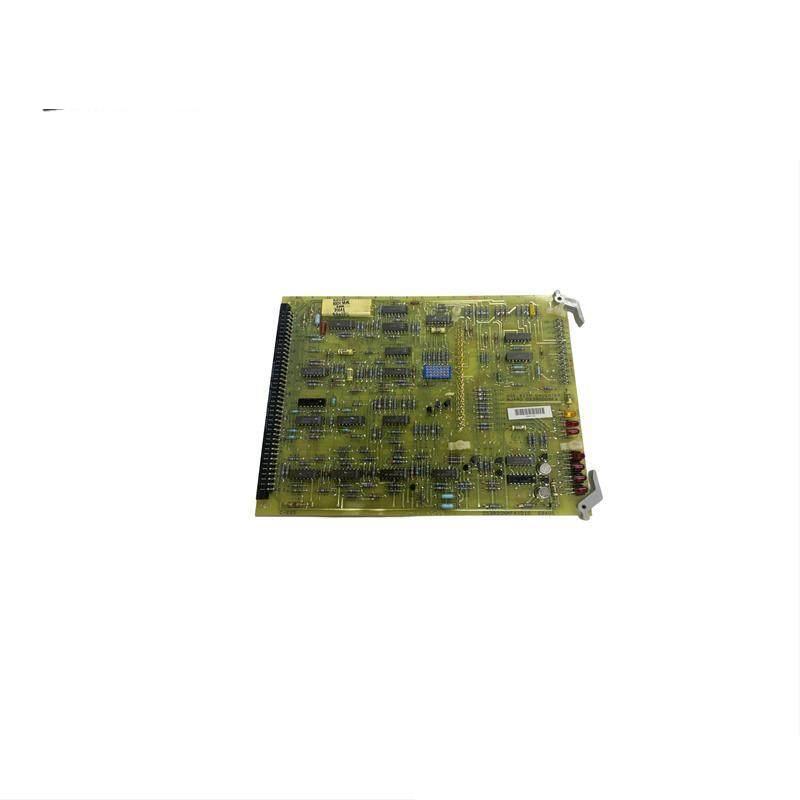

The GE IS215UCVEM09A is a high-performance input module designed for Mark VI Turbine Control Systems. It provides reliable and accurate signal processing for industrial turbine applications.

The GE IS215UCVEM09A is a high-performance input module designed for Mark VI Turbine Control Systems. It provides reliable and accurate signal processing for industrial turbine applications.

WhatsApp

WhatsApp

Manufacturer:GE Industrial Solutions

Model Number:IS215UCVEM09A

Module Type:Input/Output

Series:Mark VI

Module Classification:VMIVME-7698

Operating Voltage:24 VDC

Communication Protocol:Ethernet/IP, Profibus

Input Channels:16

Output Channels:16

Operating Temperature Range:-40°C to +85°C

Storage Temperature Range:-55°C to +125°C

Humidity Range:0% to 95%, non-condensing

Weight:0.5 kg

Dimensions:190mm x 160mm x 40mm

The GE IS215UCVEM09A is a cutting-edge input module meticulously engineered for integration into GE‘s advanced Mark VI turbine control systems. Designed for demanding industrial environments, this module delivers unparalleled precision and reliability.

With its robust construction and wide operating temperature range, it ensures stable performance even under extreme conditions. The module is compatible with various Mark VI systems, making it a versatile choice for diverse applications.

This high-performance module is equipped with state-of-the-art input capabilities, allowing seamless data collection and processing. Its compact design and lightweight construction make it easy to integrate into existing setups without compromising on functionality or efficiency.

The GE IS215UCVEM09A boasts a high environmental protection rating (IP65), safeguarding it against dust, moisture, and other environmental hazards. Additionally, it meets stringent safety and quality standards, including CE, UL, and CSA certifications, ensuring peace of mind for users.

Whether you’re upgrading your current system or building a new one, the GE IS215UCVEM09A is a top choice for those seeking a reliable, efficient, and high-performing input module for their Mark VI turbine control needs.