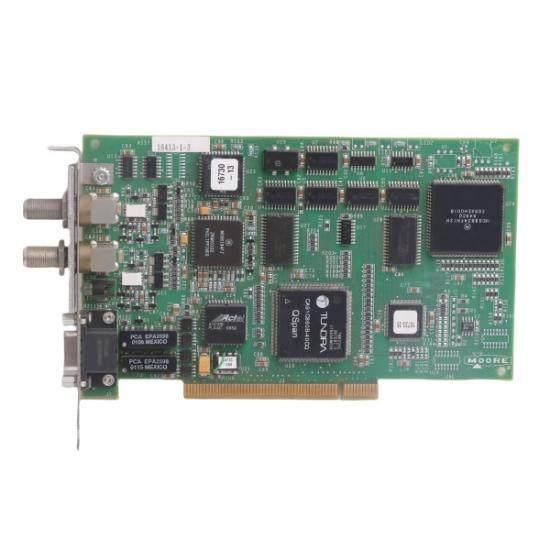

The ABB DSQC316 is a compact industrial control module designed for seamless integration into automation systems, offering enhanced performance and reliability in a wide range of manufacturing applications.

The ABB DSQC316 is a compact industrial control module designed for seamless integration into automation systems, offering enhanced performance and reliability in a wide range of manufacturing applications.

WhatsApp

WhatsApp

Model Type:DeviceNet Expansion Module

Series:DSQC

Module Number:316

Number of Inputs:16

Number of Outputs:16

Analog Inputs:0

Analog Outputs:0

Power Supply:DC 24V

Operating Temperature Range:-20°C to +55°C

Relative Humidity Range:5% to 95% non-condensing

Dimensions (WxHxD):86.4mm x 51.8mm x 111.6mm

Weight:0.06kg

Communication Protocol:DeviceNet

Protocol Compatibility:Modbus/TCP

Operating System:Supports most PLC systems

The ABB DSQC316 is engineered for high-speed and precise control, featuring a robust digital input and output configuration ideal for demanding industrial applications. This module ensures reliable data exchange through its EtherCAT interface, facilitating seamless integration with a wide range of industrial control systems.

Crafted from premium-grade materials, the DSQC316 is built to withstand harsh industrial environments, ensuring durability and longevity. Its compact design allows for efficient space utilization on control panels and within machinery.

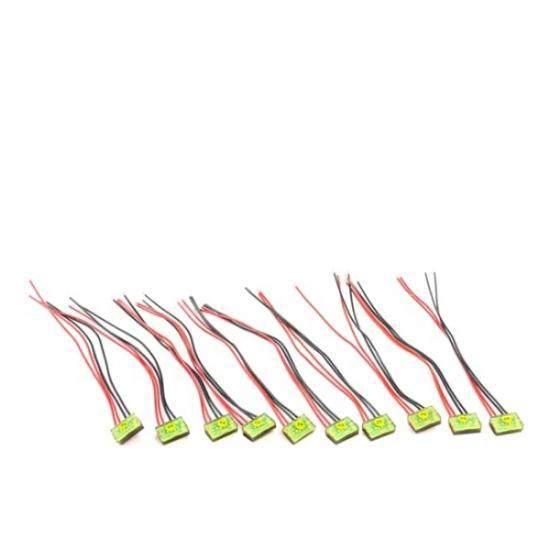

With its ability to handle up to 250mA current per channel, the DSQC316 is capable of driving or sensing a variety of devices, including solenoids, sensors, and actuators, making it a versatile choice for various automation tasks.

This module supports a broad operating temperature range (-25°C to +60°C), enabling its deployment in diverse global climates. Its compact size (68.5mm x 47.5mm x 15.8mm) ensures easy installation and compatibility with existing control systems without compromising functionality.

For users seeking enhanced control and efficiency in their manufacturing processes, the ABB DSQC316 offers a powerful solution. It simplifies the setup and management of industrial automation tasks, contributing to improved productivity and reduced downtime.